|

Contact the seller in advance before paying for the order! Cloisonne Jewelry – Artistic Beauties Of Glass And Metal

I am sure you have seen Cloisonne jewelry, and probably also have some beautiful pieces in your jewelry box. If so, you know how amazing this enameling technique is with its small, delicate, colorful cells with shiny, polished metal in between. So there is no wonder that it has mesmerized us for thousands of years.

A brief history: Cloisonnè is French and means cell or compartment, and that is what is so distinct about this jewelry style. Cells filled with glass and separated by wirework. It evolved in the Middle East and spread from there on throughout the Byzantine Empire and further on to China in the 14th century. The Chinese then perfected it and are still known for their artistic ways of using this enameling technique. Some of the best pieces in the world come from the Ming dynasty (1449 – 1457) and their particularly beautiful blue colored enamel, called Jingtai blue is famous. The first written reference to the technique in China comes from 1388, where it was referred to as “Dashi” ware, which means Muslim ware, as it came from the Islamic world. Today cloisonne still has a profound oriental influence, and lots of enameled jewelry and beads come from China. Although it is said to have originated in the Middle East, the first cloisonne-enameled pieces ever found were in graves dating back to the 12th century BC in Cyprus. The findings were small rings with very thin wires used for the cells. So perhaps the Greeks are the true inventors of it? The history is a bit blurred around who actually invented it, though. The Egyptians are also mentioned, using glass or glass paste embedded in gold, although the techniques they used was more mosaic like works, and not seen as true Cloisonne.

Anyway, as it spread throughout the world, artisans perfected the technique, heightening the beauty of the glass and wire work. The lovely wire work was perfected by the Byzantine. They began using thinner wires which made it possible to make more intricate and delicate patterns, which was more suitable for jewelry. The Byzantine Empire is famous for their love for gold therefore there is no surprise that they used backgrounds of gold in their enamel works, just like they did with their amazing mosaics. In Japan the technique is known as “Shippo”. The Japanese were large producers of Cloisonne and produced high quality pieces, but in more recent times, the mid 19th century. The technique also spread to Russia during the regime of the last Tsar and to the house of Faberge and Khlebnikow. Today the technique is very much alive and is widely used by jewelry designers around the world. So, now you know the history of Cloisonne, but how is it made, and what does it look like? Making Cloisonne jewelry: To make the enamel fondant, vitreous glass is ground to fine powder in a mortar and washed to remove impurities. It is then mixed with a very dilute solution of gum tragacanth, which is a natural gum.. The compound consists of silica nitre and lead oxide to which metallic oxide is added for coloring. The fondants are then added to the cells/cloisonne's, with a brush or fine spatulas, and left to dry. When completely dry, the piece is fired in a furnace or kiln to melt the powders in the fondant. The fondant shrinks when it melts, so the cells must be filled and fired again, until the wanted result is achieved.

Depending on how the cells are filled, we speak of three types:

Today the wires are no longer soldered onto the metal base as soldering may cause the enamel to discolor and form bubbles. So today the base metal is fired with a thin layer of clear enamel. The wire is then glued onto the enameled surface with gum tragacanth. When the gum has dried the piece is fired, and the gum burns away leaving no residue. With our modern techniques we now often electroplated the wires to prevent them from tarnishing and corrosion, and to leave the exposed areas shiny and bright.

You can get this kind of enamel jewelry in a huge variety of quality, from highly valuable hand created to mass-produced cheaper pieces. Still you are in no doubt that it is a Cloisonne, due to its use of small, artistic, colorful cells and shiny wires in between. Cheap or expensive, they are small pieces of art. Cloisonne is of course not the only enameling technique. Over the long time span it has been a popular niche of our jewelry making traditions, it has split into several unique techniques, only related through the use of wire and enamel. You have techniques like Guilloche, Plique-a-jour a technique very similar to Cloisonnè, Basse taille and Champleve. The beautiful jewelry you see on this page are made by Evelyn Sadovsky. Take a look at her fabolous jewelry on her Etsy page: EsEnamels Return from Cloisonne Jewelry to Jewelry Making Techniques Leave a comment ,I would love to hear your opinion on this page. Good or bad, it will help me making this Site better. |

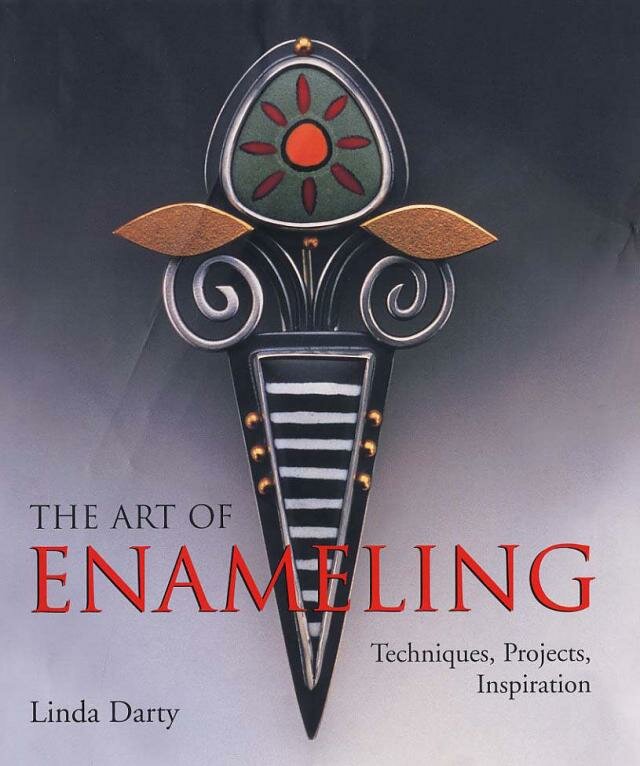

Read More About Cloisonne And Enameling

|

|

|

|

|

|

|

Promote Your Page Too